Heat Exchanger Tubesheets & Precision Drilling Services

The UAE’s Premier Tubesheet Drilling Facility (Est. 2003)

Since our foundation in 2003, high-precision drilling has been the core of Saitech Industries. While others dabble in general machining, we have dedicated over two decades to perfecting the manufacturing of Tubesheets, Baffles, and Header Pipes for the Middle East’s energy sector.

Located strategically in JAFZA, our facility is equipped to handle heavy-tonnage components that smaller workshops cannot touch. We don't just drill holes; we engineer flow paths. From emergency retubing support during shutdowns to new capital project fabrication, our ISO-certified processes ensure 100% hole concentricity and zero deviations.

Our Core Expertise:

-

Heavy Drilling: Tubesheets up to 10,000mm diameter.

-

Deep Boring: Specialized fluid ends and manifolds.

-

Logistics Advantage: Instant access to Jebel Ali Port for rapid export."

Why Precision Matters: The Risk of Poor Drilling

In heat exchanger fabrication, a deviation of just 0.1mm can lead to tube binding, assembly delays, or fatal leaks during operation. Precision drilling is not optional—it is critical.

At Saitech, we replace manual layout methods with CAD/CAM-driven CNC Drilling. This ensures:

-

Perfect Alignment: Baffles stack seamlessly with tubesheets, cutting your assembly time in half.

-

Ligament Integrity: We prevent 'breakthrough' between holes, even in high-density patterns.

-

Tube Expansion Safety: Reamed holes (H7/H8 tolerance) ensure a hydraulic seal that holds pressure for years.

Whether it is a Condenser, Boiler, or Pressure Vessel, our drilling guarantees the mechanical stability your asset needs.

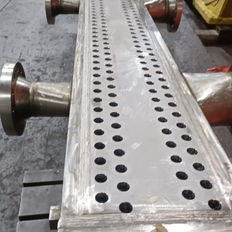

Our Tube Sheet & Baffle Drilling Capabilities

-

High-Density Drilling: 5,000+ holes per sheet with zero drift.

-

Header Pipe Fabrication: Drilling and beveling of heavy-wall pipes and manifolds.

-

Complex Geometries: Stacked drilling, angled holes, and multi-axis boring.

-

Materials: Expert handling of Carbon Steel, Stainless Steel (304/316), Duplex, and Inconel.

-

Retubing Support: Reverse engineering worn-out plates for exact replication.

Key Benefits of SAITECH’s Drilling Services

-

High Precision: Consistent hole location accuracy for optimal tube fitment

-

Reduced Assembly Issues: Accurate drilling minimizes tube misalignment and leakage risks

-

Fast Turnaround: Leveraging 20+ years of experience, we offer 24/7 emergency drilling services for plant shutdowns.

-

Cost Efficiency: Fewer reworks and better first-time fit

-

Custom Capability: Suitable for complex layouts and non-standard designs

Materials We Machine

We drill tube sheets and baffles in a wide range of materials, including:

-

Carbon steel

-

Stainless steel (304, 316, duplex)

-

Alloy steels

-

Nickel alloys

-

Cladded Plates (Explosion bonded)

-

Special heat-resistant and corrosion-resistant materials

We hold specific WPS for Inconel & Duplex drilling

Size & Thickness Capability

-

Thin to thick plates ( up to 1.5 meter)

-

Small to large diameter tube sheets ( up to 10 Meters)

-

Rectangular sheets (up to 4 X 12 Meter)

-

Custom dimensions as per client specifications

Applications of Tube Sheet & Baffle Drilling

Our services are widely used in:

-

Shell-and-tube heat exchangers

-

Condensers

-

Boilers

-

Pressure vessels

-

Process heat transfer equipment

-

Drilling of flow distribution pipes for air coolers and steam headers.

-

Retrofit and refurbishment projects

We also support repair and replacement of worn or damaged tube sheets, using reverse engineering when original drawings are unavailable.

Deep Hole Drilling & Header Pipe Fabrication

Beyond flat plates, Saitech specializes in the drilling of cylindrical components. Our deep-hole and BTA (Boring & Trepanning Association) capabilities allow us to process Header Pipes, Manifolds, and Thermowells with extreme length-to-diameter ratios.

-

Header Pipes: Precise radial drilling on heavy-wall pipes for heat exchanger distribution systems.

-

Depth Capacity: Drilling up to 1.5 meters deep with minimal runout.

-

Surface Finish: Internal burnishing available for high-flow applications

The Saitech Quality Guarantee

Since 2003, we have built our reputation on doing the difficult jobs correctly.

✔ Material Certification: Full material traceability (MTC) for every plate and pipe processed.

✔ Final Inspection: Go/No-Go gauge testing on 100% of holes before dispatch.

✔ Deburring: All baffles and tubesheets are mechanically deburred to prevent tube scratching during insertion.

✔ Project History: We hold the drawings for thousands of heat exchangers in the UAE—if we built it before, we can replicate it instantly

Need Precision Tube Sheet or Baffle Drilling?

Don't risk your timeline with unverified workshops. Trust the company that has been drilling the UAE's critical assets since 2003. Send us your drawing today.

Have questions? See our Tube Sheet and Baffle drilling in Dubai – Q&A for detailed answers